Pit Conditions

Home » Value Chain » Load & Haul » Pit Conditions

Pit Conditions

Overview

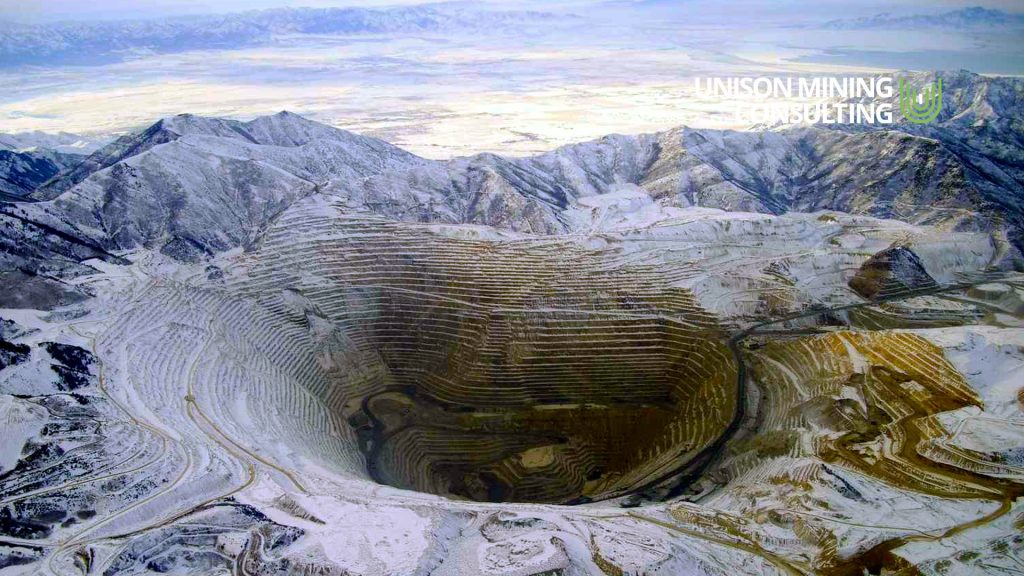

Assess pit conditions accurately for effective mine planning

Mine planning and scheduling rely heavily on accurate information about pit conditions. When conditions are well-understood and predictable, mine operators can make informed decisions about equipment deployment, workforce allocation, and production targets, while any changes in pit conditions may require adjustments to these plans on the fly.

Managing varying pit conditions on a mine site during the load and haul process presents several challenges. For one, uneven ground and changing geological conditions can increase the risk of accidents, especially when heavy equipment is involved. Operators need to ensure the safety of workers and equipment in these dynamic environments.

Varying pit conditions can also lead to excessive wear and tear on mining equipment, such as haul trucks and loaders. Maintenance becomes challenging as equipment may require more frequent servicing and repairs, inevitably impacting safety, productivity, and efficiency. Poor or inconsistent pit conditions slow the mining process, and add months and years to the LOM while mining costs continue to increase.

Key Client Challenges:

- How do we accurately assess the current state of pit conditions on a mine, including terrain, geological features, and stability?

- How do we quickly identify safety concerns or hazards related to pit conditions that need immediate attention?

- How do the pit conditions impact equipment performance, fuel consumption, maintenance needs and overall productivity and what adjustments are needed for optimal efficiency?

- What measures can we set in place to control erosion, dust, and other environmental impacts associated with pit conditions?

- How do we accurately predict and manage changes in pit conditions that could affect the quality of the mined material or ore grades?

- How can we adapt our mine plans and schedules to accommodate changing pit conditions?

- What data and technology solutions are available to monitor and track pit conditions in real time?

Mine operators need comprehensive planning tools and flexibility to adapt to changing circumstances when it comes to varying pit conditions. Specialized operator training is also crucial to ensure the proper handling of equipment in diverse pit conditions, including navigating different terrains and adapting to changing loads.

Effective data collection and real-time monitoring are also important for informed decision-making. The integration of advanced technology solutions like remote sensing, GPS, and automation for tracking equipment performance, is growing increasingly common as a solution to manage varying pit conditions.

Our experts at Unison Mining can work closely with your teams to develop a strategy to manage pit conditions, mitigating the risks associated with geological variations. This includes strategizing and implementing the processes, systems, controls and KPIs needed to incentivize behavior changes needed adjust to new ways of working with technology, new and improved ways of handling equipment, and adhering to clear and defined roles and responsibilities in assessing risk.

Lacking data to validate or support key business decisions

Lack of knowledge to define a cohesive business or data strategy

Low speed to market and trouble adapting quickly to customer and market needs

High operational costs due to lengthy data processing times

OTHER LOAD AND HAUL SERVICES

Road Management

Cycle Time Management

Payload Improvement

Delay Management

Queue Management

Fragmentation Strategy

Data & Analytics Strategy

Dispatch Strategies

Dispatch Optimization

Pit Conditions

Pre-Spotting & Double-Sided Loading

WHY UNISON MINING

Experience

Our mining experts have experienced first-hand the day-to-day complexities and issues that arise at the mining face, giving them a higher level of understanding and insight to meet your challenges.

Practical Solutions

By implementing level-appropriate transformation tools, our behavioral and cultural change methodologies, data management, and analytics, our goal is to create a sustainable and positive impact on your mining operations.

Results-driven

We go beyond strategy to offer a direct and measurable approach to success. Our commitment extends to delivering real business outcomes and helping your team sustain those changes for the long haul.