Lead Time Reduction

Home » Value Chain » Supply Chain Management » Lead Time Reduction

Lead Time Reduction

Overview

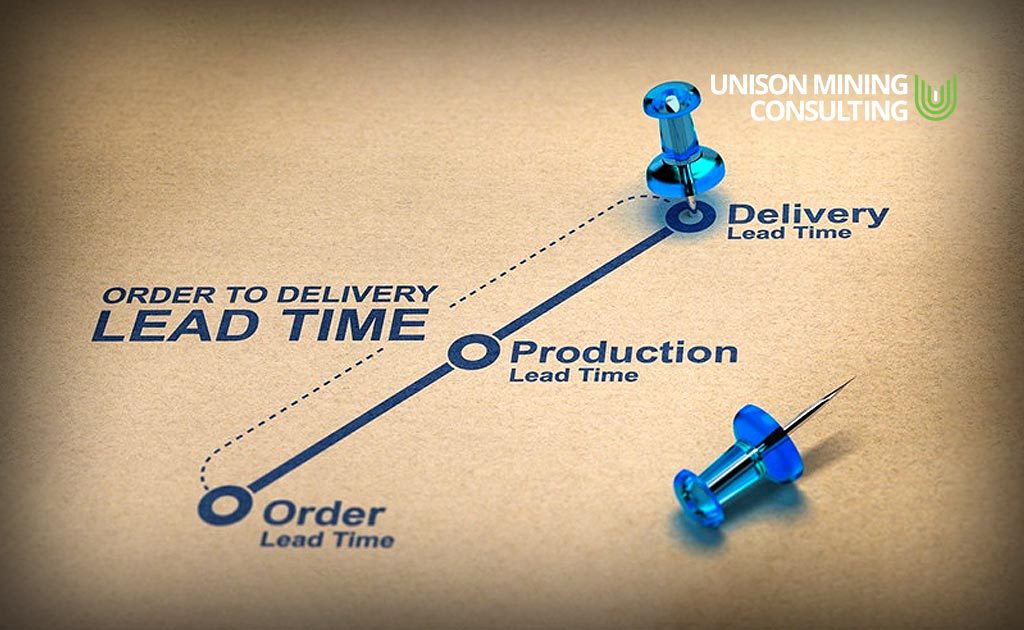

Ensure sufficient lead times through better supply chain planning and communication with suppliers

Complex and remote operations, fragmented supply chains, uncertain demand forecasting, and inventory management complexities can all contribute to longer lead times for mining companies. As such, accurate inventory forecasting, strategic planning, and high supply chain visibility are all crucial to quickly detect and manage delays.

While the mining supply chain has many variables that remain unpredictable, such as fluctuating demands for commodities, companies now have the means to hedge against these risks. By optimizing supply chain processes, building strong relationships with suppliers, and managing inventory health, mine operators can ensure their resilience to external factors and ensure lead times are minimized.

Key Client Challenges:

- How do we improve the accuracy of our inventory forecasting and projections to prevent delays as a result of inaccurate estimations?

- How do we quickly detect and manage potential bottlenecks through supply chain mapping or process re-engineering?

- How do we enhance communication and supply chain visibility for better tracking and faster detection of delays?

- How can we effectively develop and maintain strong relationships with our suppliers for reduced lead times?

- Is there room for process automation or digitization within our supply chain to minimize manual tasks and save time?

By asking these questions and implementing appropriate strategies and solutions at every stage of the supply chain, mining companies can effectively reduce lead time and manage bottlenecks before they create knock-on effects.

Lacking data to validate or support key business decisions

Lack of knowledge to define a cohesive business or data strategy

Low speed to market and trouble adapting quickly to customer and market needs

High operational costs due to lengthy data processing times

OTHER SUPPLY CHAIN MANAGEMENT SERVICES

Lead Time Reduction

Procurement

Inventory Management

Sourcing

Logistics & Transportation

WHY UNISON MINING

Experience

Our mining experts have experienced first-hand the day-to-day complexities and issues that arise at the mining face, giving them a higher level of understanding and insight to meet your challenges.

Practical Solutions

By implementing level-appropriate transformation tools, our behavioral and cultural change methodologies, data management, and analytics, our goal is to create a sustainable and positive impact on your mining operations.

Results-driven

We go beyond strategy to offer a direct and measurable approach to success. Our commitment extends to delivering real business outcomes and helping your team sustain those changes for the long haul.